|

24/7 automated production with zero downtime to enhance productivity and create maximum business

|

|

|

|

Dear [FIRSTNAME],

24/7 automated production with zero downtime to enhance productivity and create maximum business profit is an ideal prospection for most of the organizations. More... |

|

TOP STORY |

|

|

|

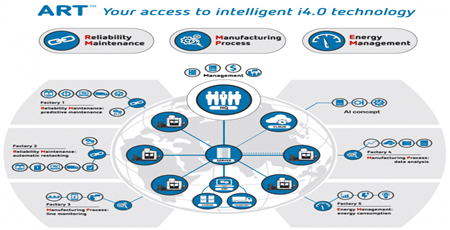

Intelligent machine and reliable automation

ARTTM system is developed by Buffalo Machinery to achieve 24/7 automated production with zero downtime and to enhance productivity and create maximum business profit and to support Industry 4.0 compatible machine tool. It is established with three core functions and 10 sub-applications to optimize the production with high reliability, energy efficiency and production control. It prepares high-tech interfaces for the manager, operator, and service to easy access the machine data. More... |

|

TECHNICAL HIGHLIGHT |

|

|

|

Drying with IoT, cloud-based data management

A SMARTER world has emerged around us, and the IoT revolution is changing the way companies are doing business, helping them to work smarter and achieve better outcomes than ever before. For years the industrial processing sector has lagged behind the consumer market in cutting edge computing technology. Here are 10 ways the new frontier is changing the old models of dryer operations as we know them.

More...

|

|

|

Arburg on the digital future of plastics production

Arburg has more than 30 years of expertise in IT networked manufacturing, which makes it easy for the company to move into the digital arena. From digital-assisted software packages to preventive maintenance and remote services, from the new portal service website to the company's own MES system, as well as the central production management system ALS, Arburg shows off all aspects of IT networking and more efficient production of plastic parts. More...

|

|

|

|

Smart manufacturing is a necessity, not a choice

3D printing, data-driven human/process/machine control, vertically and horizontally integrated automation, ubiquitous connectivity, vehicles that drive themselves are all examples of accelerating trends that have been shaping the manufacturing industry and will continue to do for years to come. These technologies have one thing in common: they all fall under the movement digitalising the manufacturing industry, which we call today Industry 4.0.

More...

|

|

|

Sorting robot on an axis

For 26 years, the storage and sawing technology from KASTO has provided dependable service to the hydraulics specialists Liebherr-Components Kirchdorf GmbH. However, to reliably meet the increasing demands in the cylinder production in the future, the company decided to modernise and expand the system. KASTO retrofitted the existing bar storage system and one of the two sawing machines with state-of-the-art technology. More...

|

|

|

More productivity for micromachining and 3D printing

The diverse demands of customers and applications are stretching laser processing’s technological boundaries ever further. In 3D printing, key criteria include performance and dynamics – i.e. maximally efficient processes with high throughput. And the micromachining field is expanding its application spectrum from classic drilling and structuring of large-area components all the way to functionalizing surfaces. More...

|

|

|

Hermle introduces another digital component

The digital transformation is now becoming the focus of many different production operations. Hermle is there to provide support while you chart your individual course towards Industry 4.0 and the smart factory. They offer a wide range of software solutions for improving your efficiency, precision and productivity, with its digital components representing links in the smarter production chain. More...

|

|

|

|

|

|

|

|

|

|